Intro to Soldering

Safety

- Many people are warded off by the elemental lead content in leaded solder. While it's true that lead is poisonous and can accumulate in your body, it really only applies to ingesting lead. People often assume the fumes may contain lead, but when you soldering, you are changing solid metal into its liquid phase — it does not get anywhere near the temperature required to turn lead into its gaseous phase (1,749°C or 3,180°F). It's possible that by handling solder that you can get trace amounts of lead on your hands, so make sure to wash your hands afterwards to avoid the possibility of getting it in your mouth.

- Solder fumes CAN be harmful. The fumes are produced by burning flux or rosin inside of rosin-core solder. While you can consult the material data safety sheet of your solder and flux to determine the toxicity of it; it's generally recommended to buy or make (very cheaply!) a fume extractor to suck fumes away from your face while soldering. To avoid breathing in fumes, it may be a good idea to take a breath before applying heat, and slowly exhale above the fumes to blow them away. Avoid blowing directly at the soldering joint, as that may cause pre-mature cooling of the joint.

- When clipping any excess leads, hold the leads between your fingers and clip the excess off with flush cutters or wire cutters. If the leads are too short to grip, close your eyes to avoid the possibility of the lead shooting into your eye — as this can easily damage your eyes.

- Turn off your iron if you aren't planning on using it in the next 10 minutes. Don't leave the room with the iron still on.

Iron Oxidation Warning

| If you take anything away from the page, let it be this information. Oxidized tips make soldering much harder and is the cause of many bad solder jobs. |

You want your soldering iron tip to always be shiny, not dull or blackened (oxidized). Leaving your iron on without a bit of solder on it will naturally oxidize it. Between each solder joint you make, you should get in the habit of dipping your iron into a brass wool tip cleaner or scrape it across a wet sponge to remove the oxidation. When you turn off your iron, ALWAYS cover it with a layer of solder before turning it off, as the solder will protect it from oxidizing while powered off. Not doing these things is a large reason that people have problems soldering or keep replacing their tips — as very oxidized tips are almost impossible to work with. A well-maintained tip should last for years.

Equipment

See the Recommended Soldering Equipment page for suggestions of equipment. At the very least, you should have:

- A temperature controlled iron

- Leaded solder

- Tip cleaner

- High performance flux

- Good desoldering braid to fix mistakes

- Wire stripper, recommended 26-30 AWG

- Copper (not copper plated) wire - stranded or solid core

Stripping Wires

Using Manual Wire Strippers

- Identify the gauge (AWG) of wire you are using and find the slot marked for that gauge on the stripper.

- Place the wire in the slot, with enough wire sticking through to work with. A good rule of thumb is to strip only enough length for the pad you are soldering to or an inch or less for wire-to-wire soldering.

- Squeeze the wire strippers and pull the wire to remove the external sheathing. If it seems to have cut into the metal of the wire, redo it at one gauge size up.

Using Automatic Wire Strippers

- Place the wire into the slot, inserting it to strip the desired amount off. A good rule of thumb is to strip only enough length for the pad you are soldering to or an inch or less for wire-to-wire soldering.

- Squeeze the wire strippers and pull the wire to remove the external sheathing. You can then pull the extra sheath off of the wire.

General Technique

Ideal temperature

Check solder datasheet for temperature ranges. Try a little bit above the lowest temperature that the solder will melt and see how it performs. Soldering or desoldering a component to a large metal piece or ground plane will require a higher temperature as the metal will absorb the heat that is applied.

Pad to Pad Bridging

Pad-to-pad bridging is one of the very few cases that you may not want to use flux, as it can make large solder beads on the pads instead of bridging. To make a bridge:

- Touch the iron to a pad for about 1 second and add enough solder to make the pad rounded.

- Repeat the first step with the other pad.

- Heat one pad and drag the liquidized solder from one pad to the other so they are both molten and make a connection. Do not blow on it to cool it.

Wire to Pad (+ pad with hole)

The most common soldering connection is soldering wires to pads or vias — pads that cross between different layers of the board such as top to bottom.

- If using stranded wire, add some excess solder to your iron and add it to your stripped wire so it becomes one non-stranded piece of wire.

- If using flux, add enough to cover the joint. If not using flux, ensure you are using rosin-core solder.

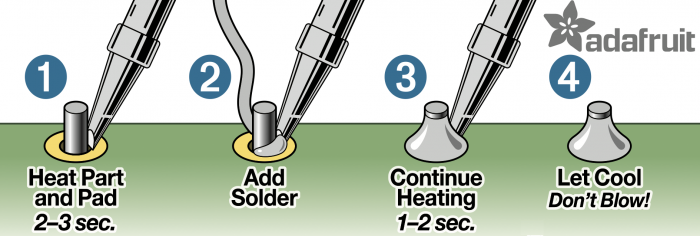

- Touch hot iron to pad and lead simultaneously for about 1 second.

- Add 1mm-3mm of solder under the tip (not on top of the tip).

- Continue holding the iron there for about 1 second. You should see the solder attach to both the lead and the solder pad.

- Pull your iron away and place it in its stand.

- Allow the joint to cool on its own. Do not blow directly on the joint, as it can cause the joint to form oddly.

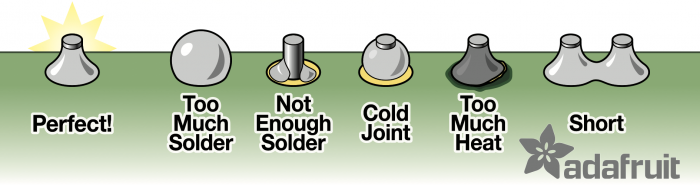

- Check your work against the #Checking Solder Joints chart. If you need to add more solder, reheat the joint and add more solder.

Wire to Wire

Often times you will need to solder two wires together or add a thru-hole resistor/capacitor/diode to a wire.

- Strip half an inch to an inch of the end of the wire(s) you will be attaching to.

- If using stranded wire, add some excess solder to your iron and add it to your stripped wire so it becomes one non-stranded piece of wire.

- Stick the wire through a length of heat shrink tubing that will be long enough to cover the future joint.

- Dip the exposed end of the wire(s) and component(s) into paste flux (if using).

- If you have "helping hands" or some other small clamping system, clamp each of the wires with the tips of the wires overlapping.

- Twist the ends of the wire over one another so they they spiral around each other.

- Add a drop of liquid flux to the exposed wire ends (if using).

- Touch hot iron to the spiraled wires simultaneously for about 1 second.

- Add 1mm-3mm of solder under the tip (not on top of the tip).

- Continue holding the iron there for about 1 second. You should see the solder flow and connect both wires.

- Pull your iron away and place it in its stand.

- Allow the joint to cool on its own. Do not blow directly on the joint, as it can cause the joint to form oddly.

- Gently pull on the wires to ensure that the connection is solid.

- Move the heat shrink tubing up the wire to cover the joint. Heat using a hot air station set to 100°C. Depending on the tubing, a hair dryer or heat from a lighter may work.

Thru-Hole Components

- Insert the component's leads into the holes.

- For resistors, diodes, non-polarized capacitors, and non-coil inductors: Bend them into a U-shape so it sits flat on the board.

- For polarized capacitors, bend the leads at angles without bending them up inside the capacitor can. The positive lead must attach to the positive pad, and the negative lead must attached to the negative pad.

- On the opposite side of the board, bend the leads outwards about 45 degrees so that the resistor stays in place.

- If using flux, add enough to cover the pad. If not using flux, ensure you are using rosin-core solder.

- Touch hot iron to pad and lead simultaneously for about 1 second.

- Add 1mm-3mm of solder under the tip (not on top of the tip).

- Continue holding the iron there for about 1 second. You should see the solder attach to both the lead and the solder pad.

- Pull your iron away and place it in its stand.

- Allow the joint to cool on its own. Do not blow directly on the joint, as it can cause the joint to form oddly.

- Check your work against the #Checking Solder Joints chart. If you need to add more solder, repeat the process.

- Check electrical continuity.

- Hold the leads between your fingers and clip the excess off with flush cutters or wire cutters. If the leads are too short to grip, close your eyes to avoid the possibility of the lead shooting into your eye — as this can easily damage your eyes.

Surface Mount Soldering

See the Surface Mount Soldering page.

QSBs

Quick Solder Boards (QSBs) are boards that are designed to sit on a motherboard with pads perfectly aligned to solder pads on the motherboard. This reduces the amount of wires you may need as it replaces many wire connections with just needing to bridge solder from the QSB pads to the motherboard pads. You simply place them on the motherboard in their designated spot, then bridge the pads from the motherboard to the QSB. While they make for very quick and easy installs, they can be difficult to remove as they are flush to the board and solder can be connected under the board.

Checking Solder Joints

Unknown Component Markings

Resistors: Resistors reduce current in series and reduce voltage in parallel. Resistors have two leads and are not polarized — meaning they can be soldered onto the board in either orientation. Generally, boards mark resistors with the letter R followed by a number on the board (such as R13) to uniquely identify it on a schematic. If you have an unknown value thru-hole resistor, you look at the color bands on it and use the chart below to determine the value.

Capacitors: Capacitors temporarily store voltage and smooth out changes in voltage. They can be polarized (positive and negative sides) or non-polarized. Generally, boards mark capacitors with the letter C followed by the number on the board (such as C13) to uniquely identify it on a schematic. Generally, capacitors will list their capacitance (pF, μF, F) and their max voltage rating (V). Capacitors come in a variety of shapes as shown below.

Inductors: Inductors temporarily store current in the form of a magnetic field and smooth out changes in current. They are generally not polarized — meaning they can be soldered onto the board in either orientation. Generally, boards mark resistors with the letter L followed by a number on the board (such as L13). Inductors come in a variety of shapes as shown below.

Diodes: Diodes force electricity to flow in one direction. As such, they are always polarized — meaning they must be soldered in the correct orientation so that current flows in one direction. Generally, boards mark resistors with the letter D followed by a number on the board (such as D13). Diodes come in a variety of shapes as shown below.

Fixing Mistakes

Not Enough Solder

If you did not use enough solder, simply reheat the solder joint and add more solder.

Too Much Solder

If you added too much solder and it looks like a sphere on top of the board, simply hold solder wick on top of it and heat the wick to absorb some of the solder. Then, reheat the remaining solder to make a good joint. Some websites advise heating and then physically slapping the board to splash the excess solder off — but this is messy, can potentially splash solder on other components, and put unnecessary force on the board causing fragile joints or traces to potentially break.

Unwanted Bridge

If you accidentally bridge two components, hold solder wick on top of them and heat the wick to absorb some of the solder. Then, reheat the remaining solder to make a good joint. Using flux may also help prevent creating a bridge, as it will be less likely to try and follow your iron when you pull away.

Troubleshooting and Tips

- Wires do not accept solder or turn dark colored

- Likely this indicates that you are using aluminum wire or copper-clad aluminum wire. Aluminum wire is silver colored and oxidizes rapidly, resulting in the oxidation layer burning when you try and solder it. Copper-clad wires have an aluminum core surrounded by copper plating and is difficult to solder to.

- Can't bridge pads

- Try not using flux. This will allow you to drag the solder around more freely and make the bridge.

- Solder wick doesn't pick up solder

- Try adding flux to the wick. Good wick has flux (rosin) built in.