Game Gear:Region Switch Mod

Game Gear systems fall into two regions, Japanese and export. With one exception, Game Gear games are not region locked but a number of games will change language accordingly, and some will even have extra content when played on a Japanese system. Thankfully, it is possible to change region on any Game Gear fairly easily, though the method will vary depending on motherboard revision.

Overview

Region is controlled by a single pin on the 315-5378 SCA on VA0 consoles (pin 24) or on the main ASIC on later revisions (pin 142), usually labeled as "JAP" in service manuals. This pin works in identical fashion to the region selection pin on the Genesis/Mega Drive; the system is set to export or English mode if it is held high (5V), and is set to Japanese if it is held low (GND). By isolating the pin and wiring it to either 5V or GND, the system's region is changed appropriately. On VA5 and 171-7923A boards, the region selection pin is given two sets of jumpers, making this modification even easier to accomplish. If desired, the region pin can be wired to a SPDT switch mounted in the system for fast and convenient region switching.

Materials and Tools

Materials

- Leaded solder

- Flux (not required but highly recommended)

- Hookup wire (optional)

- SPDT switch (optional)

- Cordless drill with step bit (optional)

Tools

- 4.5 mm gamebit screwdriver

- Small JIS screwdriver

- Soldering iron

- Razor blade

Important Note

Make sure that your Game Gear is fully working and recapped before attempting this!

General Disassembly

This procedure applies to all Game Gears regardless of region or revision.

- Flip the Game Gear face down on a soft surface to avoid scratching the screen lens. Use a 4.5 mm gamebit screwdriver for the security screw in the cartridge slot, and a small JIS screwdriver for the remaining six screws holding the system together. One screw is hidden inside each of the battery compartments.

- Carefully pull the back half off and tilt it away from you. Disconnect the power, audio and speaker connectors on the back half to fully separate the two halves.

- Though not required, it is highly recommended to remove the motherboard from the front shell. Remove the small JIS screws along the perimeter of the motherboard, but do not remove the four screws around the center near the screen, as these secure the entire screen assembly to the motherboard and are not attached to the shell. Undo the two large JIS screws on each side of the cartridge port to release the motherboard.

- If you remove the motherboard, this will leave the bare LCD screen exposed. Make sure to set the screen on a soft, lint-free surface to avoid scratching the LCD or getting excessive dust on it.

Procedure for VA0 (twin ASIC)

- Locate the SCA. It is labeled "315-5378" and is the ASIC located closest to the cartridge port.

- With the bottom of the board facing you, count the pins on the left side of the SCA from the bottom up. The 7th pin from bottom (pin 24) is the region pin.

- Using a razor blade, very carefully cut the trace going to pin 24. Alternatively you can lift pin 24, but this requires some finesse as the pin is delicate and you may risk bending adjacent pins.

Permanent Region Change

- If you have a Japanese system and want to change it to be an export system, wire pin 24 to any 5V source. Pin 35 of the cartridge port or pin 2 of the SCA are convenient areas for this.

- If you have an American or European system and want to change it to be Japanese, wire pin 24 to any ground source. Pin 19 of the SCA or pin 41 of the cartridge port are convenient areas for this.

Region Switch

- Wire the center tap of a SPDT switch to pin 24, one of the side taps to 5V and another to GND.

- Find a clear area to mount your switch, one where the switch will be largely out the way when holding the system. Using a step bit, drill an appropriate size hole in the shell. Mount the switch and route the wires so they will not be in the way of the screw bosses or other parts of the shell.

Procedure for VA1 and VA4 (single ASIC)

- Locate pin 142 of IC1. With the bottom of the board facing you, count the pins on the top of the ASIC from left to right. The third pin from left is pin 142.

- Using a razor blade, very carefully cut the trace going to pin 142. Alternatively you can lift pin 142, but this requires some finesse as the pin is delicate and you may risk bending adjacent pins.

Permanent Region Change

- If you have a Japanese system and want to change it to be an export system, wire pin 142 to any 5V source. Pin 35 of the cartridge port or pin 28 of IC2 (IC3 on VA4) are convenient areas for this.

- If you have an American or European system and want to change it to be Japanese, wire pin 24 to any ground source. Pin 14 of IC2 (IC3 on VA4) or pin 41 of the cartridge port are convenient areas for this.

Region Switch

- Wire the center tap of a SPDT switch to pin 142, one of the side taps to 5V and another to GND.

- Find a clear area to mount your switch, one where the switch will be largely out the way when holding the system. Using a step bit, drill an appropriate size hole in the shell. Mount the switch and route the wires so they will not be in the way of the screw bosses or other parts of the shell.

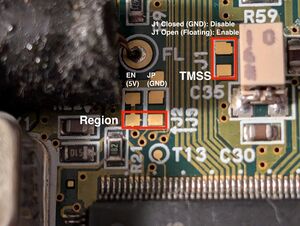

Procedure for VA5 and 171-7923A

- Locate jumpers J2 and J3, which are located to the right of the backlight and above IC1. The lower pads of both jumpers are connected to pin 142 of IC1, with the upper pad of J2 going to 5V and the upper pad of J3 going to GND.

- Cut the trace connecting the upper and lower pads of J2, which will isolate pin 142. Do not cut the horizontal trace connecting the two lower pads.

- If you wish to permanently convert your system to a Japanese one, bridge J3 with a blob of solder or a small length of wire. The system can be easily converted back by removing J3 and shorting J2 again.

Region Switch

- Wire the center tap of a SPDT switch to one of the lower pads of either J2 or J3. The upper pads of J2 and J3 will go to each side tap of the switch.

- Find a clear area to mount your switch, one where the switch will be largely out the way when holding the system. Using a step bit, drill an appropriate size hole in the shell. Mount the switch and route the wires so they will not be in the way of the screw bosses or other parts of the shell.